Full treatments for a cancer drug can be difficult for thousands of people

A Twin Cities Mom’s Story of Drug Supply Crisis and the Baby Formula Shortage in the Earlier Stages of the Winter Solving Crisis

Drug manufacturers say they are busy with children’s medications and are planning to increase sales during the winter months. They didn’t know that it would be bad or that it would start early.

David Margraf is a research scientist with the Resilient Drug Supply Project at the University of Minnesota and he says that shortages are hitting a lot of different patient populations with different drugs.

Margraf said they were all a different tale. “There’s commonalities between them, but each one is a little bit different and it’s very tedious trying to figure out what’s going on sometimes.”

In order to give an early warning to clients when trouble is on, many of the raw ingredients that go in to making drugs are just two countries, China and India. A recent easing of China’s zero Covid policy may affect supplies of many products, including medications.

Even with normal levels of production, high demand during a tough cold and flu season – like the one the US is experiencing – can make it hard for families to find what they’re looking for.

Whitney Hemsath, a writer and mother of four living in the Twin Cities area of Minnesota, said she has been noticing how little children’s medication has been on store shelves for a few weeks, but she wasn’t too worried since the family still had some at home.

Last week, though, her 4-year-old woke up in the middle of the night with a throbbing ear and she discovered they were out of pain medication.

She searched for a store that was open at 5:00 a.m., and found one with three bottles of children’s acetaminophen left. There was no ibuprofen, which lasts longer, and no generics or store brands. While she was grateful to find something, she says the family is on a tight budget while her husband finishes his Ph.D., so paying for the brand name medicine was frustrating.

She said she felt bad complaining because she was lucky to find what she needed, but she did not know how long it would take.

She said that it hadn’t been like this before. You’re lucky if they have any brand of medicine that you want because they used to have so many options.

Bare shelves in some stores may seem reminiscent of this year’s baby formula shortage, but the situations aren’t quite the same. With formula, a major manufacturer recalled products and shut down one of its factories and conducted a nationwide recall after the government found quality problems at the production facility, taking it offline for months. The shutdown exacerbated existing supply chain problems, leaving shelves empty.

MajorUS manufacturers of children’s medications such as Perrigo in Michigan and Johnson and Johnson in Pennsylvania are operating facilities 24 hours a day, 7 days a week, according to the Consumer healthcare Products Association.

The US Food and Drug Administration also says it is keeping a close eye on the situation and “talking daily” with manufacturers to find ways to increase supply.

“The ibuprofen and acetaminophen and children’s formulations, we’re monitoring those really closely at this time,” said an FDA official who spoke to CNN on the condition of anonymity because they were not authorized to share details of the agency’s work.

Trade-Offs in Pharmaceutical Supply Chains: The United States Pharmacopeia and Drug Enforcement Agency Reveals an Executive Order on the Supply Chain of Active Ingredients

“There are not any manufacturing problems, so there’s not anything that’s slowing production down or causing these shortages as far as manufacturing. In fact, manufacturers are working very closely with us and increasing supply so that we can get the demand where the priority needs to be,” the official said.

The official would not confirm specific requests from the companies. The official said that they are working very closely with them, because they are picking up on the offers.

The FDA says the number of drugs reported in shortage decreased from a high of 251 in 2011. There were 41 drug shortages tracked by the FDA in 2021, for example. That same year, the agency says, it averted 317 shortages.

Adderall, for example, saw a sharp increase in demand from 2020 to 2021. A leader in manufacturing reported delays due to worker shortages. The company has confirmed to CNN that the worker shortage is over.

Because Adderall is a controlled substance, it is tightly regulated by the government. The Drug Enforcement Administration may limit how much can be made to avoid patient abuse.

Most of the drugs that seem to disappear are inexpensive generics given by injection. They have strict manufacturing requirements that make them costly to produce and slimmer profit margins, making them less economic incentive for companies to make them.

Other generics – like many antibiotics – are vulnerable to shortages, too. It was experts who said that happened to some of the drugs.

A senior director of the United States Pharmacopeia said economics was what determines the quality standards for diet supplements, food and drugs.

For the past three years, USP has been tracking pharmaceutical supply chains through its Medicine Supply Map in order to help identify and head off potential shortages.

She said the supply chain wouldn’t absorb the shock of the demand increase because of the surge in the flu and Covid.

The official told CNN that they are encouraging companies to let them know if there is an increase in demand so that they can work with them early on.

Biden issued an Executive Order on America’s Supply Chains in February of this year that instructed the Secretary of the Department of Health and Human Services to identify and report any potential risk in the supply chain for pharmaceuticals and their active ingredients.

“HHS, for the first time in its history, has established a new dedicated public health industrial base expansion and supply chain management office, with the goal of building resilience,” White House spokesperson Kevin Munoz wrote in an email to CNN.

Dino Carlone, the earliest cancer patient, learned that Bacillus Calmette-Guérin had a great track record

Dino Carlone was frightened when he was diagnosed with bladder cancer three years ago, but his spirits were buoyed when he learned that he could get help from a highly effective drug with a great track record.

“You’re telling yourself, ‘OK, I have cancer, and it’s a very aggressive cancer, but I’ve got great therapy. Carlone, 65, said there’s great numbers.

Carlone was supposed to receive treatment for several years, but he says he only got it for only a few months because his urologist told him there was a shortage of the drug, called Bacillus Calmette-Guérin, or BCG.

Bladder cancer patients receive six rounds of treatment after surgery and as many as two more a year or two depending on the patient, according to Davies. The catheter that delivers the drug directly to the bladder is put in the doctor’s office.

“This is a terrible crisis. Laura Bray, a board member of the End Drug Shortages Alliance, said that they should be doing everything they can to give every single patient the best chance of survival. “It’s heartbreaking, and we must do better.”

A spokesperson for Merck, the sole maker worldwide of BCG, wrote in an emailed statement that the company increased production of the drug by 200% between 2012 and 2019 and has been producing it “to the full extent of manufacturing capacity over the past several years.”

While bladder cancer is becoming more common, the market for the drug is still small and requires a significant investment.

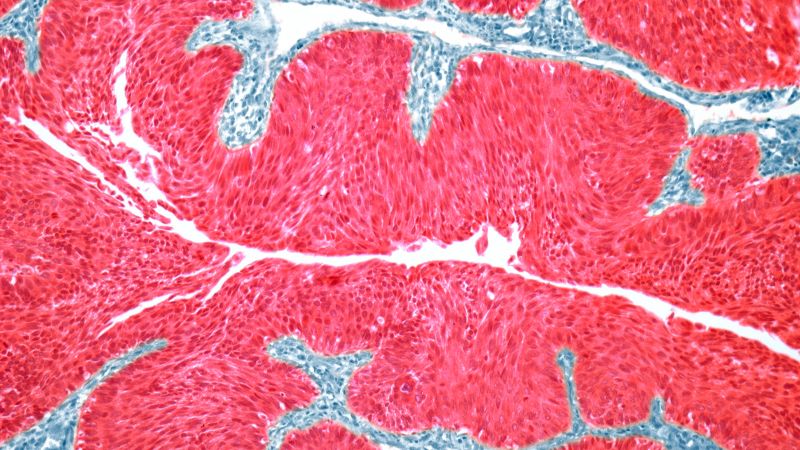

When BCG became available in 1976, it was considered a breakthrough strategy. It is used as a vaccine against cancer because it contains weakenedbacteria that will cause the immune system to fight it.

Source: https://www.cnn.com/2023/02/15/health/cancer-drug-shortage-bcg/index.html

Comment on the FDA’s ban on prescribed blood creatino (BCG) dosages in a cancer research community and how pharmaceutical companies need to act fast

“It’s a very, very frightening circumstance to realize that at that point, what they deem to be an aggressive cancer could in fact come right back,” he said.

All of them said they had to use at least one strategy to deal with the BCG shortage, and four of the centers said they couldn’t give BCG at all, according to the report.

Some medical centers said they are dividing some of the patients’ doses. They often use a vial for more than one patient because it’s supposed to be used for one patient. An instructor at the University of Utah College of Pharmacy, Fox said that the whole of a vial needs to be used within six hours of opening.

According to the FDA statement, the agency “cannot require a pharmaceutical company to make a drug – or make more of a drug – even if it is medically necessary. In addition, we don’t control how much a drug is distributed or who gets priority.

It would be difficult for pharmaceutical companies to increase production or make drugs that aren’t very profitable, said Wosiska.

Dr. Yoram Unguru is a member of the core faculty at the Berman Institute of Bioethics and he said that pharmaceutical companies can make profits while keeping up with demand for essential medicines.

“The federal government must take a more hands-on approach and maintain a critical stockpile of essential lifesaving medicines and set prices for medications, akin to existing rate-setting bodies that oversee public utilities,” he said.